Magnuson Hot Rod 2650 Jackshaft Bearing Support

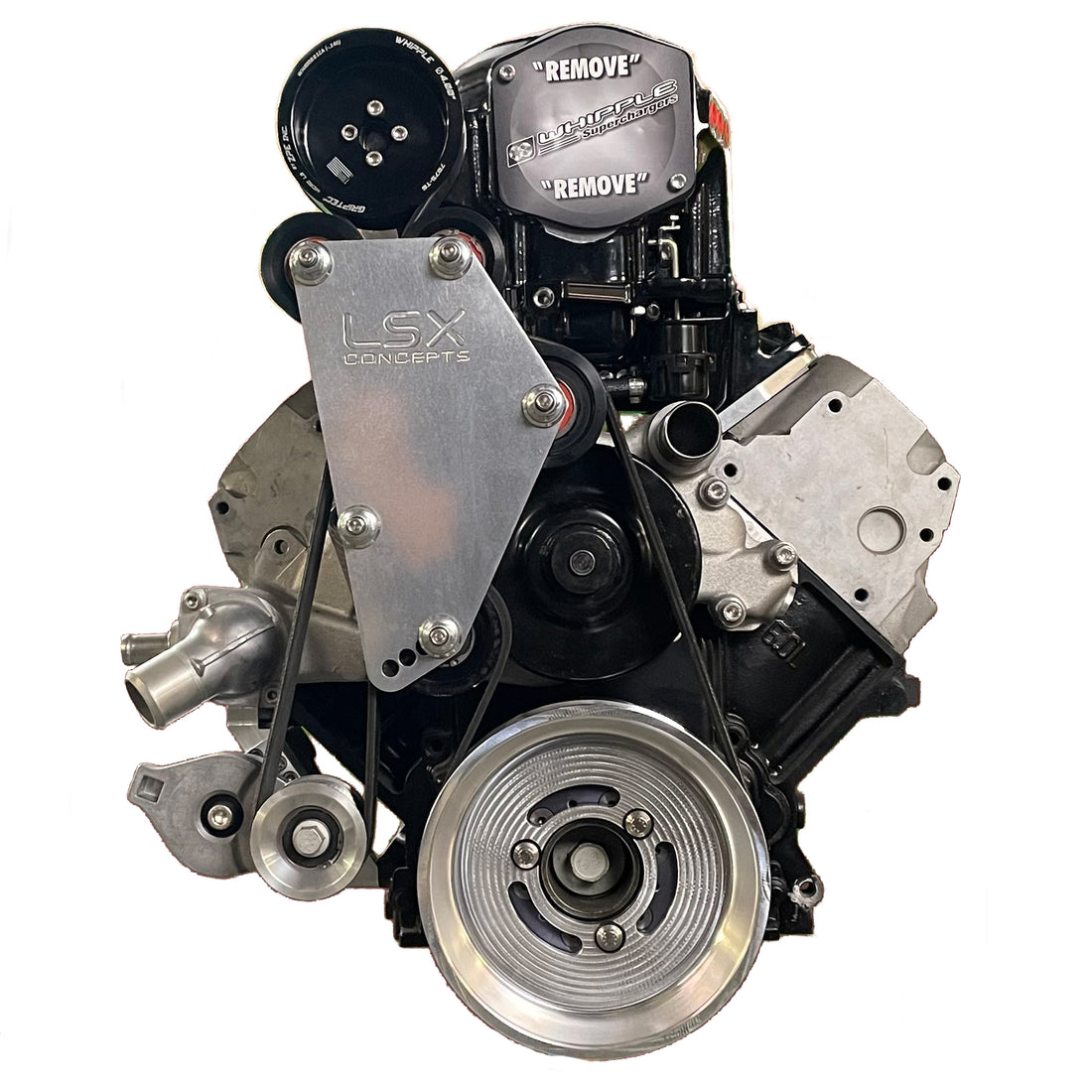

All aftermarket superchargers are well-designed. It’s the performance enthusiast that goes far beyond what was the intended use. When the Magnusson 2650 Hot Rod Supercharger came on the market, we developed a rigid tension Magdrive for it based on our very successful LSA Race Drive. As the envelope was pushed by users with higher overdrive ratios, we started to see failures. We also concluded the high overdrive ratios failed to produce their expected results.

Failures in the Magnusson Superchargers were primarily jack shaft failures. The failures were the steel end coming off the carbon fiber shaft. Upon a closer look at the damaged shafts, it appeared the steel ends were not completely glued. We suspect that during assembly the air pressure inside the tube pushed the glue from the joint. There is not a vent hole to relieve the internal pressure during assembly.

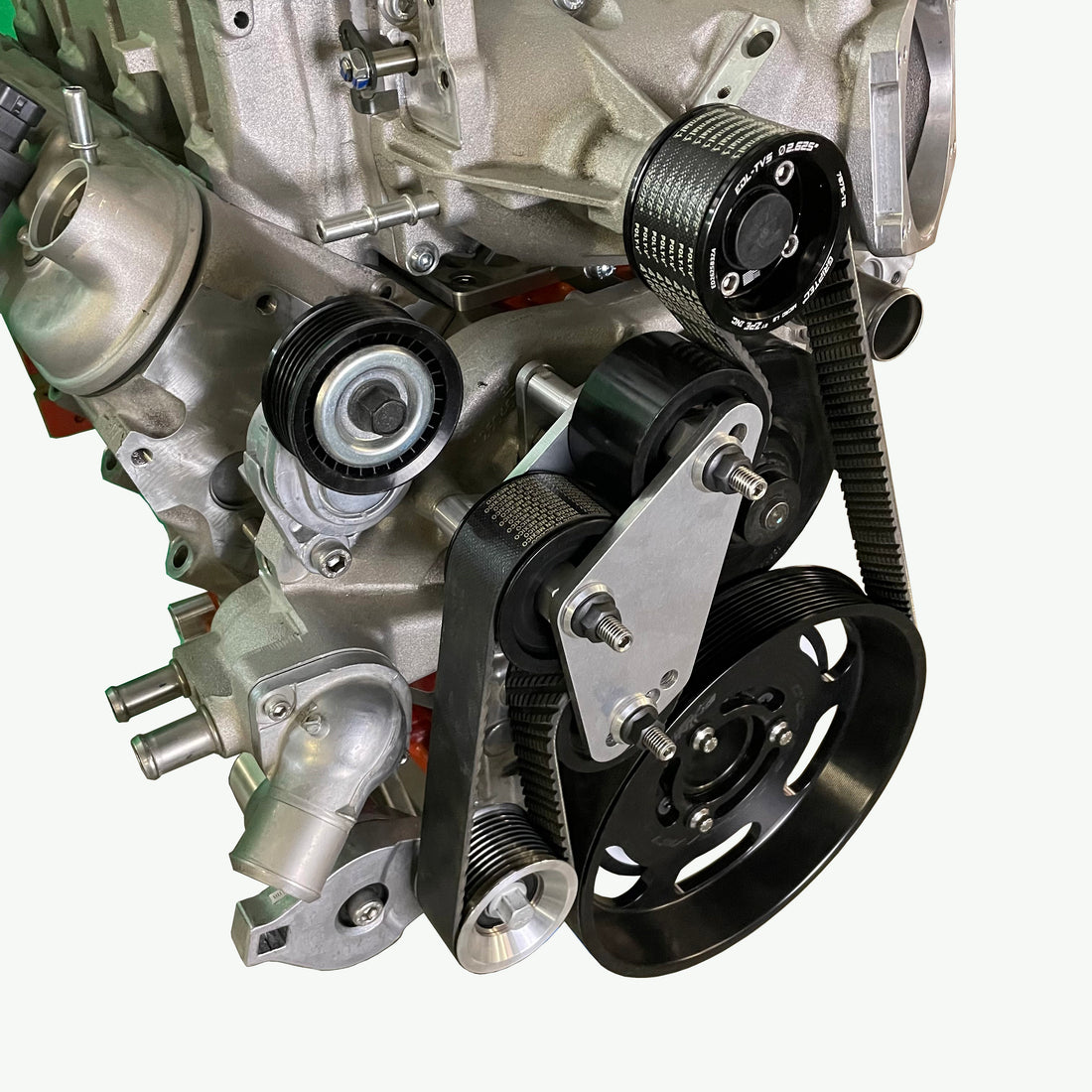

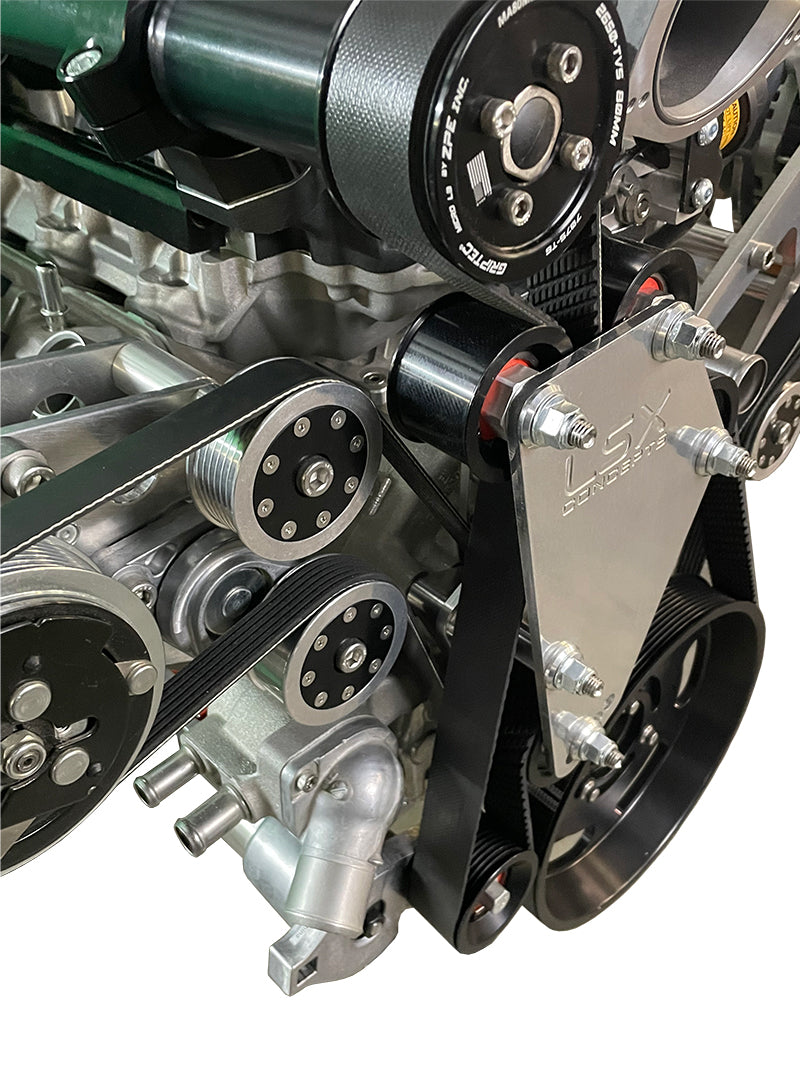

We were also trying to develop a system that kept the belt more evenly tensioned at the higher RPM and Horsepower ranges capable with the 2650 series rotors. That led to our creating and testing of our Flexdrive tensioner design on our proven Magdrive design. Our Flexdrive tensioner has a cloverleaf adjustment device that allows you to keep the belt in its “sweet spot”.

Using the Flexdrive tensioner system on a Magdrive, we discovered it became much more difficult to install the Belt so we redesigned the Magdrive creating a complete Flexdrive system. It simplified belt installation while also having additional adjustments allowing an even broader selection of belts. The Flexdrive system allows the belt to be installed and tensioned before the installation of the front cover.

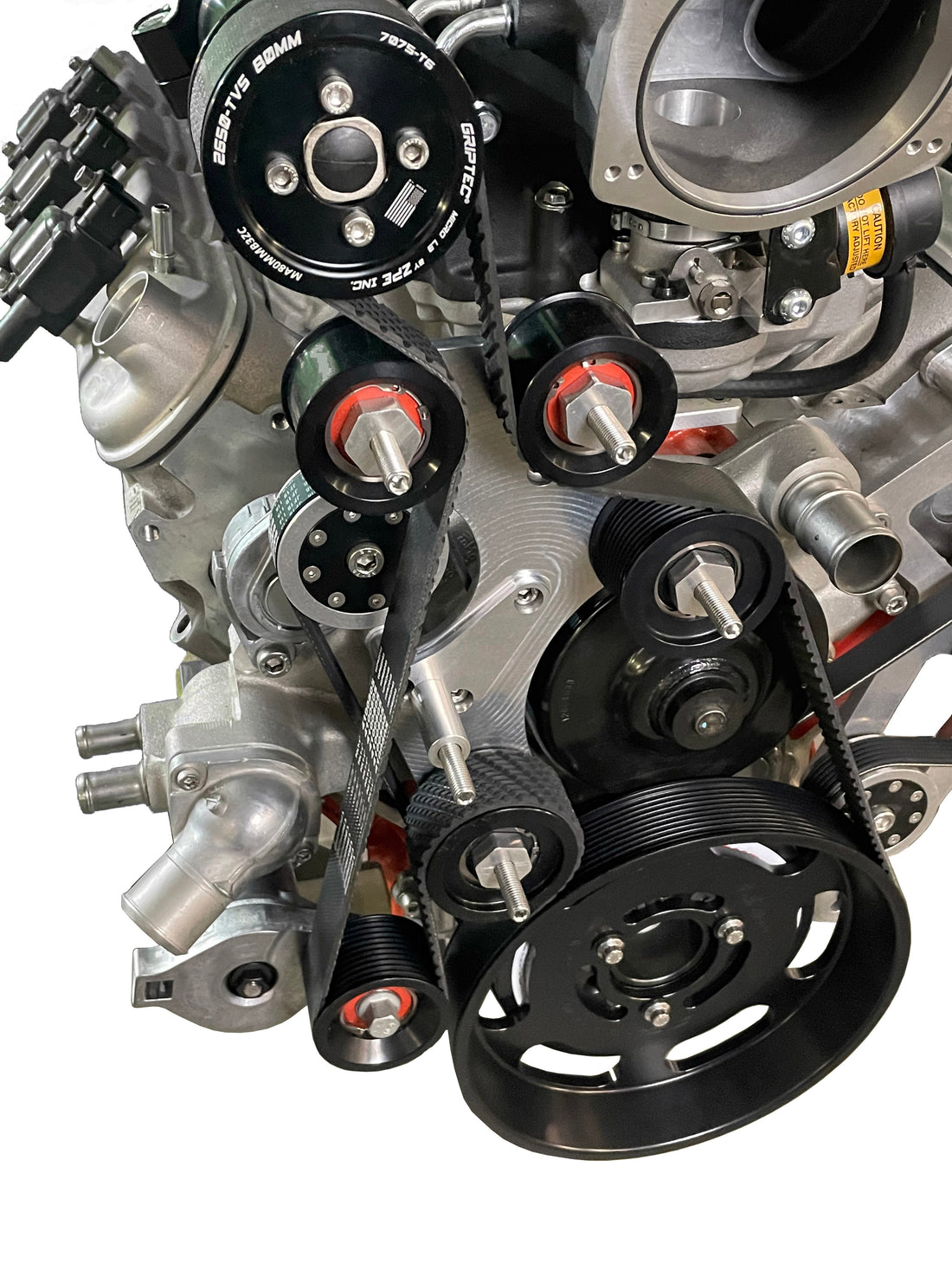

The Flexdrive accomplished our goals but something seemed to be missing. We placed some cameras under the hood to take a look. We discovered the pulley on the jackshaft would bend to what we believe was excessive. The pulley bending would allow the belt to run only on the rearward ribs under high loads. A wider belt with more ribs proved almost nothing.

Not to be deterred, we built some test jackshaft supports to run on an actual supercharger used in racing applications. The support made the jackshaft pulley run true and increased blower pressure at high speeds. Since using the support we have not broken a shaft on sevral test cars.

Running test parts allows us to redesign and produce a more user-friendly design. We made the Support smaller while giving extra clearance for the extra large throttle bodies and snouts. The best part it’s easy to install.

Failures in the Magnusson Superchargers were primarily jack shaft failures. The failures were the steel end coming off the carbon fiber shaft. Upon a closer look at the damaged shafts, it appeared the steel ends were not completely glued. We suspect that during assembly the air pressure inside the tube pushed the glue from the joint. There is not a vent hole to relieve the internal pressure during assembly.

We were also trying to develop a system that kept the belt more evenly tensioned at the higher RPM and Horsepower ranges capable with the 2650 series rotors. That led to our creating and testing of our Flexdrive tensioner design on our proven Magdrive design. Our Flexdrive tensioner has a cloverleaf adjustment device that allows you to keep the belt in its “sweet spot”.

Using the Flexdrive tensioner system on a Magdrive, we discovered it became much more difficult to install the Belt so we redesigned the Magdrive creating a complete Flexdrive system. It simplified belt installation while also having additional adjustments allowing an even broader selection of belts. The Flexdrive system allows the belt to be installed and tensioned before the installation of the front cover.

The Flexdrive accomplished our goals but something seemed to be missing. We placed some cameras under the hood to take a look. We discovered the pulley on the jackshaft would bend to what we believe was excessive. The pulley bending would allow the belt to run only on the rearward ribs under high loads. A wider belt with more ribs proved almost nothing.

Not to be deterred, we built some test jackshaft supports to run on an actual supercharger used in racing applications. The support made the jackshaft pulley run true and increased blower pressure at high speeds. Since using the support we have not broken a shaft on sevral test cars.

Running test parts allows us to redesign and produce a more user-friendly design. We made the Support smaller while giving extra clearance for the extra large throttle bodies and snouts. The best part it’s easy to install.